Helitaanka qalabka ugu habboon ee gears

Marka la nashqadeynayo iyo soo saarista qalabka, agabka la isticmaalay waxay ku xidhnaan doonaan nooca qalabka la samaynayo iyo sida iyo meesha loo isticmaalayo.

Waxaa jira noocyo badan oo alaabta ceeriin ah oo sida caadiga ah loo isticmaalo qaab-dhismeedka qalabka, iyo shay kastaa wuxuu leeyahay sifooyinkiisa makaanikada ugu fiican waana doorashada ugu fiican.Qaybaha ugu muhiimsan ee alaabta waa naxaas naxaas ah, birta daawaha, aluminium aluminium iyo thermoplastics.

1. Alloys Copper

⚙️Markanaqshadaynta qalabkataas oo lagu salayn doono jawi daxalaysa ama u baahan in ay noqoto mid aan magnet-ka ahayn, daawaha naxaasta ah ayaa inta badan ah doorashada ugu fiican.

⚙️Saddexda alloys ee ugu badan ee naxaasta lagu isticmaalo gears waa naxaas, phosphor bronze, iyo aluminium bronze.

⚙️Garshyada inta badan laga sameeyo naxaasta daawaha waamarshooyin kiciniyo racks waxaana loo isticmaali doonaa meelaha rarka hooseeya.

⚙️Phosphor bronze waxay wanaajisaa caabbinta xidhashada iyo adkaanta daawaha.Daxalka sarreeya iyo iska caabbinta xirashada waxay ka dhigayaan alloys phosphor bronze ah doorasho aad u fiican oo loogu talagalay qaybaha sare ee darawalnimada.Tusaale:qalabka gooryaanka

⚙️Aluminium bronze waa daawaha saddexaad ee naxaasta ah ee loo isticmaalo gears.Alwaaxyada naxaasta aluminiumku waxay leeyihiin iska caabin ka sarreeya xirashada marka loo eego alloys bronze fosfoor sidoo kale waxay leeyihiin iska caabin sare oo daxalka.Gearsyada caadiga ah ee laga soo saaro aluminium aluminium naxaas ah waxaa ka mid ah gears helical ah oo la tallaabay (gears helicical) iyo qalabka gooryaanka.

2. Biraha birta

⚙️Marka anaqshadaynta qalabkawaxay u baahan tahay xoog walxo sare leh, birta birta ayaa ah doorashada ugu fiican.Qaabkeeda ceeriin, birta cawl waa la tuuri karaa oo lagu farsamayn karaa gears.

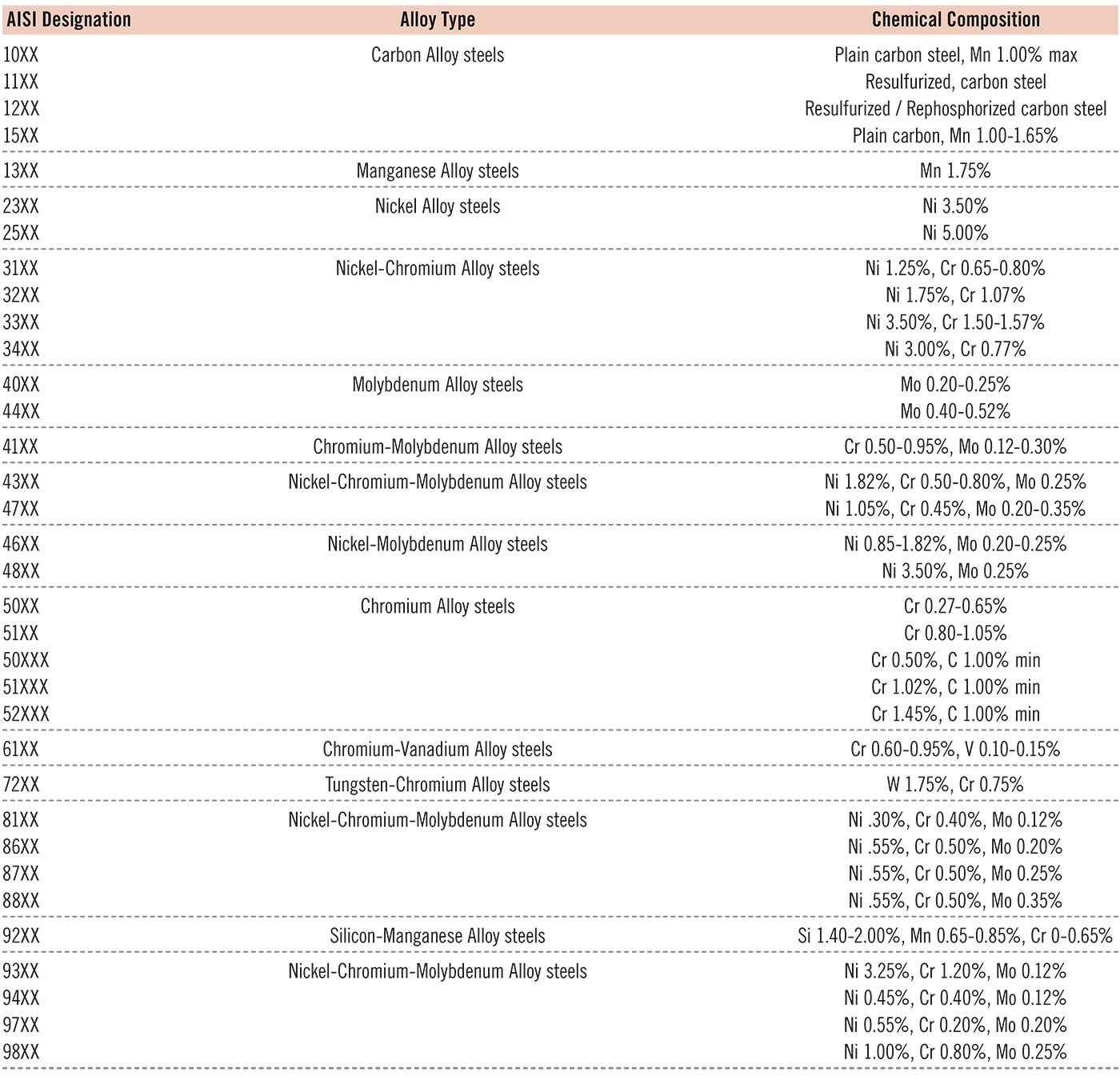

⚙️Waxaa jira afar tilmaamood oo waaweyn oo ah daawaynta birta: birta kaarboonka, birta daawaha, birta aan birta lahayn, iyo birta qalabka.Alloys-Steel Alloys waxaa loo isticmaalaa ku dhawaad dhammaan noocyada gearing sababtoo ah way fududahay in la mashiin, waxay leeyihiin caabbinta xirashada wanaagsan, waa la qallajin karaa, si ballaaran loo heli karo, oo aad u jaban.

⚙️Alaabooyinka birta kaarboon waxaa loo sii kala saari karaa bir khafiif ah, bir kaarboon dhexdhexaad ah, iyo bir kaarboon-sare ah.Alaabooyinka birta fudud waxay leeyihiin wax ka yar 0.30% maadada kaarboon.Alaabooyinka birta kaarboon ee sarreeya waxay leeyihiin kaarboon ka badan 0.60%, iyo birta ka kooban dhexdhexaadka ah ayaa u dhexeeya.Birahani waa doorasho wanaagsanmarshooyin kicin, gears helical, marshashka,gooryaanka, iyo gooryaanka.

3. Aluminium aluminium

⚙️Aluminium Alloys waa bedelka wanaagsan ee birta birta ee codsiyada kuwaas oo u baahan awood sare oo miisaan culus. Dhammaystirka dusha sare ee loo yaqaan passivation wuxuu ka ilaaliyaa aluminium aluminium oksaydhka iyo daxalka.

⚙️Aluminium Alloys looma isticmaali karo jawi kuleyl sare leh marka ay bilaabaan inay qalloociyaan 400°F.Aluminium aluminiumka caadiga ah ee loo isticmaalo gearing waa 2024, 6061, iyo 7075.

⚙️Dhammaan saddexdan aluminium alloys waxaa lagu daweyn karaa kulayl si loo hagaajiyo adkaantooda.Gear ka samaysan aluminium alloys waxaa ka mid ahmarshooyin kicin, gears helical, gears ilka toosan, iyo marshashka.

4. Thermoplastics

⚙️Thermoplastics ayaa ah doorashada ugu fiican ee marshada halka miisaanku yahay shuruudaha ugu muhiimsan.Gear ka samaysan balaastiigyada waxaa loo farsamayn karaa sida qalabka birta ah;si kastaba ha ahaatee, heerkulbeegyada qaarkood ayaa ku habboon wax soo saarka iyada oo la adeegsanayo qaabaynta duritaanka.Mid ka mid ah kuwa ugu caansan ee la isku duro thermoplastic waa acetal.Qalabkan waxaa sidoo kale loo yaqaan (POM).Gears waxaa laga samayn karaa polymer midkood.Kuwani waxay noqon karaanmarshooyin kicin, gears helical, giraangiraha gooryaanka, gears bevel, iyo marshashka.

Waqtiga boostada: Jul-13-2023